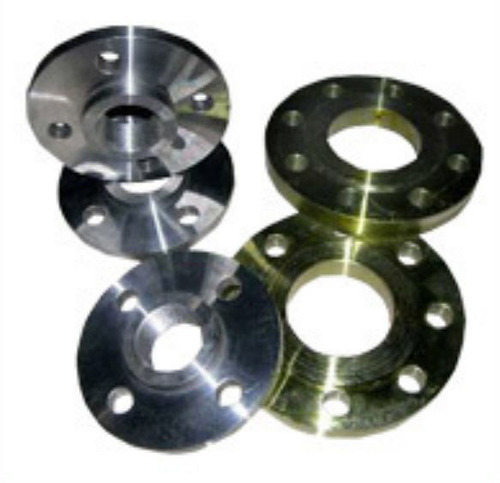

Stainless Steel Flanges.

Stainless Steel Flanges. Specification

- Length

- Customizable up to 500 mm

- Thickness

- 10 mm to 50 mm

- Material

- Stainless Steel (grades: SS 304, SS 316, SS 321, etc.)

- Color

- Silver/Grey

- Use

- Industrial pipeline connection, machinery, oil & gas, water supply, power plants, chemical plants

About Stainless Steel Flanges.

Specification

- Grades: 202, 304, 304L, 304, 304H, 316, 316L, 316Ti, 321, 321H, 317, 317L, 310, 310S, 409, 410, 420, 430 etc.

- Range: Weld Neck, Slip On, Blind, Socket Weld, Lap Joint, Spectacles, Ring Joint, Orifice, Long Weld Neck, Deck Flange, etc.

- Size: 1/8" NB TO 48"NB

- Class: 150, 300, 400, 600, 900, 1500 & 2500

Comprehensive Flange Solutions

We offer a complete range of stainless steel flanges to cater to diverse industrial needs. Whether your project demands slip on, weld neck, blind, threaded, lap joint, or socket weld flanges, our products cover size ranges from 1/2 inch NB to 48 inch NB. Each flange is designed to meet stringent standards and deliver optimal performance under varying pressure and temperature conditions.

Built for Tough Industrial Environments

Manufactured from high-grade stainless steel like SS 304, SS 316, and SS 321, our flanges exhibit outstanding corrosion resistance and can withstand temperatures from -50C up to 800C. With customizable thicknesses from 10 mm to 50 mm and lengths up to 500 mm, these flanges suit heavy-duty applications in chemical plants, power stations, and water treatment facilities.

Assured Quality and Versatility

Our stainless steel flanges conform to leading global standards like ANSI, ASME, DIN, EN, BS, JIS, and ISO. Various face typesRaised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)are available with machined, mirror, or sandblasted finishes. These features make them suitable for a wide spectrum of pipelines and industrial equipment, ensuring leak-proof and secure connections.

FAQs of Stainless Steel Flanges.:

Q: How are stainless steel flanges used in industrial applications?

A: Stainless steel flanges are used to connect pipes, valves, pumps, and other equipment in pipelines, providing a secure and leak-proof joint. They are commonly used in industries such as oil & gas, petrochemical, water treatment, and power generation due to their strength, versatility, and resistance to corrosion and high temperatures.Q: What is the process for selecting the right type of stainless steel flange?

A: To select the appropriate flange, consider your applications pressure and temperature requirements, the type of connection required (bolted or welded), face type (RF, FF, RTJ), and the specific stainless steel grade needed for corrosion resistance. Ensuring the flange meets standards like ANSI, ASME, or DIN is crucial for compatibility and performance.Q: When should I use a weld neck flange instead of a slip on or threaded flange?

A: Weld neck flanges are ideal for high-pressure or high-temperature applications due to their strength and ability to distribute stress evenly. Use slip on or threaded flanges for lower pressures and less critical systems where quick and easy installation is a priority.Q: Where are stainless steel flanges commonly installed?

A: Stainless steel flanges are installed in pipelines and machinery used across various industries, including petrochemical plants, oil & gas refineries, power plants, water supply systems, and food processing units, especially where high corrosion resistance is essential.Q: What benefits do mirror and machined surface finishes provide on flanges?

A: Mirror and machined finishes enhance the sealing performance and appearance of the flange. Mirror finishes provide smooth, corrosion-resistant surfaces suitable for sanitary applications, while machined finishes offer reliable sealing and easier installation in industrial systems.Q: How does the pressure rating influence the choice of flange?

A: The pressure rating (Class 150 lbs to 2500 lbs or PN 6 to PN 250) determines the maximum pressure a flange can handle. Select a flange with a rating equal to or higher than your systems operating pressure to ensure safety and longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in GI Fittings Category

GI Flange Fitting

Material : Galvanized Iron, Other

Color : Silver Gold

Use : other, Pipe fitting and connection in plumbing or industrial settings

Thickness : Variable (dependent on specifications)

POWERTEX MARKETING

GST : 27ALIPM3722C1ZD

GST : 27ALIPM3722C1ZD

Office No - 312, Arihant Industrial Complex CHS,

Ahmadabad Street, Masjid Bunder East,Mumbai - 400009, Maharashtra, India

Phone :08045478007

|

|

POWERTEX MARKETING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry