Norton Spitfire Laser Ultra Thin Cutting Wheel.

Price 14 INR/ Piece

MOQ : 100 Pieces

Norton Spitfire Laser Ultra Thin Cutting Wheel. Specification

- Shape

- Flat

- Toughness

- High

- Grain Type

- Aluminum Oxide

- Bonding

- Resinoid Bonded (BF)

- Backing

- Reinforced Fiberglass

- Chemical Composition

- Al2O3 (Aluminum Oxide), Resin

- Hardness

- Medium

- Material

- Aluminum Oxide

- Type

- Ultra Thin Cutting Wheel

- Grain Sizes

- A36T-BF

- Rolls Size

- Not Applicable (Disc Wheel)

- Application

- Precision cutting of metals, stainless steel, and alloys

- Maximum Operating Speed

- 15,300 RPM

- Finish

- Clean, burr-free cuts

- Thickness

- 1.0 mm

- Package Quantity

- 10 pieces per pack

- Bore Size

- 16 mm

- Color

- Black/Green

- Diameter

- 107 mm

Norton Spitfire Laser Ultra Thin Cutting Wheel. Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Norton Spitfire Laser Ultra Thin Cutting Wheel.

Experience prodigious precision and meritorious performance with the Norton Spitfire Laser Ultra Thin Cutting Wheel. Engineered for prime results, this affordable disc delivers a clean, burr-free finish on metals, stainless steel, and alloys with its ultra-thin 1.0 mm profile. Explore unparalleled durability and efficiency with a tough aluminum oxide composition and medium hardness, all at an unbeatable price. Ideal for both manufacturers and wholesalers across India, each pack contains 10 reinforced fiberglass discs, ensuring long-lasting, reliable cutting with speeds up to 15,300 RPM.

Competitive Edge & Plant Applications

The Norton Spitfire Laser Ultra Thin Cutting Wheel dominates the market with its prime ultra-thin design, offering swift, clean, and burr-free cuts with unmatched accuracy. Perfect for plant floor operations, it handles precision cutoff tasks for metals, stainless steel, and alloys. Its reinforced fiberglass backing and medium-hardness ensure durability, making it an extraordinary choice for manufacturers demanding high-performance and extra-long life in industrial cutting applications.

Sample, Export Markets & Supply Efficiency

Quick dispatch of sample units is available to help manufacturers and distributors assess the wheels prodigious capabilities. Norton offers robust logistics and timely delivery to major export markets across Asia, the Middle East, and beyond. With competitive offers and significant supply capacity, bulk orders for these resinoid bonded wheels are serviced efficiently. Benefit from Nortons reliable global logistics network and consistent supply for all your precision cutting needs.

Competitive Edge & Plant Applications

The Norton Spitfire Laser Ultra Thin Cutting Wheel dominates the market with its prime ultra-thin design, offering swift, clean, and burr-free cuts with unmatched accuracy. Perfect for plant floor operations, it handles precision cutoff tasks for metals, stainless steel, and alloys. Its reinforced fiberglass backing and medium-hardness ensure durability, making it an extraordinary choice for manufacturers demanding high-performance and extra-long life in industrial cutting applications.

Sample, Export Markets & Supply Efficiency

Quick dispatch of sample units is available to help manufacturers and distributors assess the wheels prodigious capabilities. Norton offers robust logistics and timely delivery to major export markets across Asia, the Middle East, and beyond. With competitive offers and significant supply capacity, bulk orders for these resinoid bonded wheels are serviced efficiently. Benefit from Nortons reliable global logistics network and consistent supply for all your precision cutting needs.

FAQs of Norton Spitfire Laser Ultra Thin Cutting Wheel.:

Q: How does the Norton Spitfire Laser Ultra Thin Cutting Wheel benefit industrial users?

A: This cutting wheel provides meritorious performance, delivering clean and burr-free cuts with high precision. Its durable aluminum oxide grain and reinforced fiberglass backing ensure prime quality and extended service life, making it ideal for industrial usage.Q: What types of materials can be cut with this wheel?

A: You can effortlessly cut a variety of metals, stainless steel, and alloys using this wheel. Its ultra-thin profile ensures quick and accurate cuts while maintaining a smooth and clean finish.Q: When should I choose a 1.0 mm thickness cutting wheel?

A: A 1.0 mm thickness is optimal when you require precise, burr-free, and narrow cuts on metal materials, especially for tasks demanding minimal material wastage and rapid operation.Q: Where are the main export markets for this product?

A: The Norton Spitfire Laser Ultra Thin Cutting Wheel is regularly exported to markets in Asia, the Middle East, and other regions with a significant demand for high-performance industrial supplies.Q: What is the process of obtaining a sample before bulk purchase?

A: To explore the products prodigious quality, you can request a sample from the manufacturer or wholesaler. Samples are usually dispatched quickly to help you evaluate the wheels suitability for your application.Q: What makes the finish of this cutting wheel superior?

A: The cutting wheel is designed to deliver a clean, burr-free finish on metals and alloys, reducing the need for secondary processing and ensuring high-quality results straight from the initial cut.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Abrasive Wheel Category

Norton SC Discs

Price 50.0 INR / Number

Minimum Order Quantity : 50

Shape : Round

Hardness : Yes

Material : SS

Type : Norton SC Discs

Yuri Flexible Grinding Wheel

Price 20 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Depressed Center

Hardness : Medium

Material : Aluminium Oxide

Type : Flexible Grinding Wheel

DC Wheel

Price 19 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Disc/Circular

Hardness : Medium to Hard

Material : Aluminum Oxide

Type : Abrasive Wheel

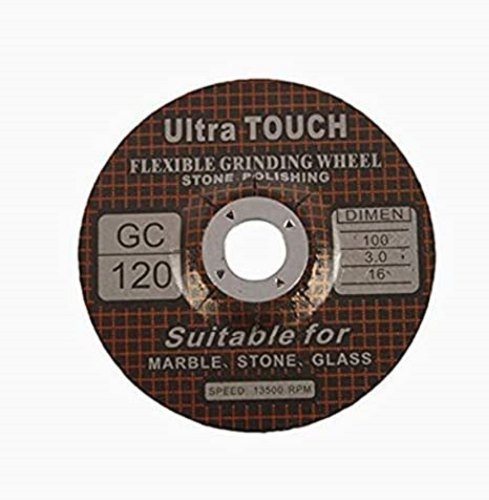

Ultra Touch Gc Wheel

Price 20 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round, Disc, Wheel

Hardness : Medium to Hard

Material : Green Silicon Carbide (SiC)

Type : Abrasion Wheel / Grinding Wheel

POWERTEX MARKETING

GST : 27ALIPM3722C1ZD

GST : 27ALIPM3722C1ZD

Office No - 312, Arihant Industrial Complex CHS,

Ahmadabad Street, Masjid Bunder East,Mumbai - 400009, Maharashtra, India

Phone :08045478007

|

|

POWERTEX MARKETING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry