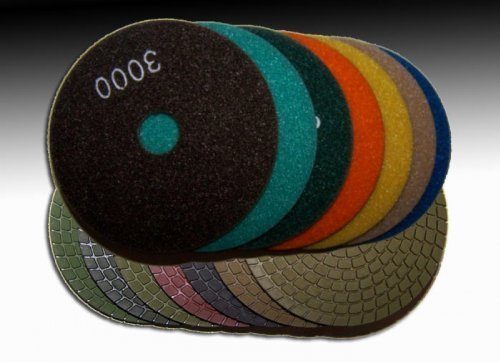

Clipper polishing pads

Price 95 INR/ Piece

Clipper polishing pads Specification

- Shape

- Rectangular / Strip

- Grain Type

- Aluminium Oxide

- Bonding

- Resin bonded

- Toughness

- High

- Hardness

- Medium

- Backing

- Non-woven

- Chemical Composition

- Aluminium oxide, synthetic resin

- Material

- Non-woven synthetic fibre

- Type

- Polishing pad roll

- Grain Sizes

- Fine, Medium, Coarse

- Rolls Size

- 100 mm x 25 m

- Strips Size

- 25 mm x 100 mm

Clipper polishing pads Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Clipper polishing pads

Directions, Features, and Plant Applications

Clipper polishing pads are easy to use-simply cut the required strip or section and mount on compatible polishing machines. Their high flexibility complements automatic or manual operations, ensuring quick, uniform finishing. Ideal for plant applications, these pads efficiently address surface preparation, general cleaning, and deburring tasks in automotive, sheet metal, and fabrication units. The brilliant design supports both wet and dry usage, minimising downtime and maximising productivity during routine industrial maintenance.

Export Markets, Packaging, and Certifications

With robust exchange agreements in place, our stock is always ready for swift dispatching to main export markets, including Europe, Southeast Asia, and the Middle East. Clipper polishing pads are meticulously packed in moisture-resistant, export-grade cartons or rolls. Every batch is certified for quality and safety, ensuring clients receive only the most reliable and rarefied finishing solutions. Trust in our seamless supply chain for every reorder and guarantee your workshop never runs out of essentials.

FAQ's of Clipper polishing pads:

Q: How should I use Clipper polishing pads for optimal results?

A: For best outcomes, cut the desired pad length and fit it on a compatible machine or use manually. Employ gentle to moderate pressure depending on the task, and utilise these pads with water or dry as needed. Always clean after each use for better longevity.Q: What materials and surfaces are Clipper polishing pads best suited for?

A: These pads are engineered for metals, especially during cleaning, surface finishing, and deburring operations. Their high flexibility and non-woven backing make them conformable and versatile for a wide range of industrial surfaces.Q: Where can these polishing pads be used in an industrial plant?

A: Clipper polishing pads are ideal for automotive workshops, machine shops, fabrication plants, and general manufacturing units requiring efficient surface treatment solutions.Q: What benefits do Clipper pads offer over traditional cleaning pads?

A: Their unmatchable flexibility, high toughness, and rarefied durability ensure longer usable life. Plus, the pads can be reused multiple times, making them cost-effective and environmentally friendly.Q: What is the process for exchanging damaged or defective pads?

A: Simply contact our customer service team with proof of purchase and a brief description or photo of the issue. We offer a straightforward exchange process to ensure your stock is always ready for use.Q: When is the best time to utilise these pads during production?

A: These pads are best employed during pre-paint surface preparation, post-weld cleaning or deburring, and final polishing stages to achieve uniform, high-quality finishes on metal components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Norton wheels Category

Norton Flap Wheel

Price 174 INR / Piece

Minimum Order Quantity : 10 Pieces

Toughness : High

Hardness : Medium to Hard

Bonding : Resin bond

Type : Flap Wheel

Norton Unified Wheel

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Toughness : High durability for consistent finishing

Hardness : Medium

Bonding : Resin Bonded

Type : Unified Wheel

Jawan Ajax Brand Aloxide RIC Belt

Price 150 INR / Piece

Minimum Order Quantity : 10 Pieces

Toughness : High toughness with durable resin system

Hardness : Medium to Hard

Bonding : Resin bond on both sides (double resin) for extra durability

Type : Resin Industrial Cloth (RIC) Belt

Norton bear premium flap disc

Price 29 INR / Piece

Minimum Order Quantity : 25 Pieces

Toughness : High

Hardness : Medium to Hard

Bonding : Resin Over Resin

Type : Flap Disc

GST : 27ALIPM3722C1ZD

|

|

POWERTEX MARKETING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry