Non Sparking Hand Tools

Price 350 INR/ Piece

MOQ : 10 Pieces

Non Sparking Hand Tools Specification

- Surface Finish

- Polished, corrosion-resistant

- Grip Type

- Anti-slip, comfortable grip

- Power Source

- Manual hand operated

- Tensile Strength

- High tensile strength, suitable for industrial applications

- Function

- For safe use in explosive environments (petroleum, chemical, gas, etc.)

- Features

- Non-sparking, anti-magnetic, corrosion resistant

- Tool Type

- Non Sparking Hand Tools

- Material

- Aluminum Bronze / Beryllium Copper

- Handle Material

- Wood / Fiberglass / Non-Sparking Metal

- Shape

- Ergonomically designed, standard tool shapes

- Dimension (L*W*H)

- Varies by tool type; standard sizes available

- Durability

- Long operational life in harsh environments

- Packaging

- Blister pack or box

- Set Options

- Available in sets or individual pieces

- Safety Standard

- Meets international safety guidelines

- Rust Resistance

- Excellent

- Application

- Ideal for petrochemical, mining, gas, and ammunition industries

- Temperature Resistance

- Up to 500°C

- Color

- Gold/Brass

- Maintenance

- Low, easy to clean and maintain

- Hardness

- Rockwell C 23-28

Non Sparking Hand Tools Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Non Sparking Hand Tools

Highly Recommended for the most demanding environments, our Non Sparking Hand Tools are the paragon of safety and reliability, sought-after by professionals in petrochemical, mining, gas, and ammunition industries. Designed for excellence, these gorgeous tools come in gold/brass hues, crafted from Aluminum Bronze or Beryllium Copper, ensuring safety with non-sparking, anti-magnetic, and corrosion-resistant features. With a high tensile strength and temperature resistance up to 500C, each piece offers an anti-slip grip for superior handling. Available at the lowest price in sets or as individual pieces-pick yours now and experience unrivaled durability and peace of mind.

Non Sparking Hand Tools: Versatility & Commercial Applications

Non Sparking Hand Tools excel in commercial settings that demand the highest safety standards. These tools are prominently used in explosive environments such as refineries, chemical plants, ammunition depots, and mines. Ideal for maintenance, assembly, repair, and construction tasks, they are manually operated with standard tool shapes and anti-slip grips for comfortable application. Thanks to their non-sparking nature, users can confidently perform tasks without the risk of accidental ignition, making them indispensable in these critical industries.

Main Export Markets, FOB Port, and Payment Valuation

Valued for their premium quality, these hand tools are consistently delivered to international markets, including Europe, the Middle East, Africa, and Southeast Asia. Orders ship securely from major Indian FOB ports, ensuring prompt domestic and international delivery. Flexible payment terms support seamless procurement for global and domestic market clients alike, accommodating diverse valuation and business needs. Buyers benefit from hassle-free transactions with various options suited to different commercial arrangements in accordance with established export standards.

Non Sparking Hand Tools: Versatility & Commercial Applications

Non Sparking Hand Tools excel in commercial settings that demand the highest safety standards. These tools are prominently used in explosive environments such as refineries, chemical plants, ammunition depots, and mines. Ideal for maintenance, assembly, repair, and construction tasks, they are manually operated with standard tool shapes and anti-slip grips for comfortable application. Thanks to their non-sparking nature, users can confidently perform tasks without the risk of accidental ignition, making them indispensable in these critical industries.

Main Export Markets, FOB Port, and Payment Valuation

Valued for their premium quality, these hand tools are consistently delivered to international markets, including Europe, the Middle East, Africa, and Southeast Asia. Orders ship securely from major Indian FOB ports, ensuring prompt domestic and international delivery. Flexible payment terms support seamless procurement for global and domestic market clients alike, accommodating diverse valuation and business needs. Buyers benefit from hassle-free transactions with various options suited to different commercial arrangements in accordance with established export standards.

FAQ's of Non Sparking Hand Tools:

Q: How do Non Sparking Hand Tools ensure safety in hazardous environments?

A: These tools are made from non-sparking alloys such as Aluminum Bronze or Beryllium Copper, which minimize the risk of sparks and accidental ignition when used in explosive or flammable settings like chemical plants, gas works, and mines.Q: What are the primary uses and industries for Non Sparking Hand Tools?

A: Non Sparking Hand Tools are ideal for use in petrochemical, mining, gas, and ammunition industries where traditional steel tools may pose ignition risks. They are typically employed for maintenance, repairs, and assembly in hazardous, explosive-prone areas.Q: When should I opt for Non Sparking Hand Tools over regular tools?

A: You should choose Non Sparking Hand Tools whenever you work in environments where fumes, dust, or flammable gases are present and there is a significant risk of explosion or fire from tool impact.Q: Where are these tools manufactured and exported from?

A: These hand tools are manufactured in India and are shipped globally from major Indian FOB ports, serving both domestic and international markets in Europe, Middle East, Africa, and Southeast Asia.Q: What is the maintenance process for Non Sparking Hand Tools?

A: Maintenance is straightforward. Simply clean the tools after use to remove debris or chemical residues. Their corrosion-resistant and polished finish makes upkeep minimal, ensuring a long operational life even in harsh industrial conditions.Q: What are the benefits of ergonomic and anti-slip design in these tools?

A: Ergonomically shaped handles with anti-slip grip provide comfort, reduce user fatigue, and improve tool control, promoting safe and efficient manual operation during prolonged use in challenging industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hand Tools Category

Clipper Glass Cutter blade

Price 110 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : High Carbon Steel

Tool Type : Glass Cutter Blade

Surface Finish : Polished / Nickel Plated

Power Source : Manual

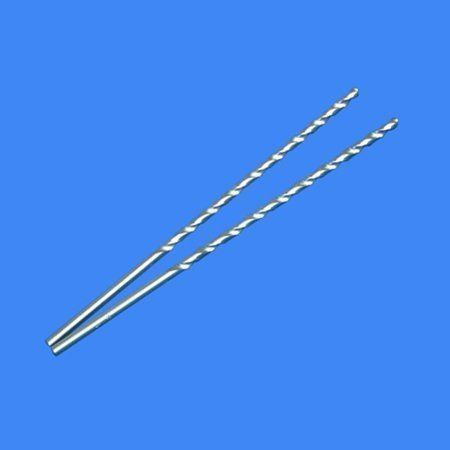

Hss Straight Shank Long Series Drills

Price 20 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, High Speed Steel (HSS)

Tool Type : Long Series Drill Bit

Surface Finish : Bright/Polished Finish

Power Source : Not Applicable (Used with Compatible Drill Machines)

Super Granite Masonry Drills

Material : Other, HighSpeed Steel (HSS) with Tungsten Carbide Tip

Tool Type : Masonry Drill Bit

Surface Finish : Polished with Sand Blasting

Power Source : Used with Electric Drill

POWERTEX MARKETING

GST : 27ALIPM3722C1ZD

GST : 27ALIPM3722C1ZD

Office No - 312, Arihant Industrial Complex CHS,

Ahmadabad Street, Masjid Bunder East,Mumbai - 400009, Maharashtra, India

Phone :08045478007

|

|

POWERTEX MARKETING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry