Hitachi Metal cutting blades

Price 175 INR/ Piece

Hitachi Metal cutting blades Specification

- Product Type

- Metal Cutting Blade

- General Use

- Cutting metal sheets, rods, pipes, and profiles

- Material

- High-Speed Steel (HSS)

- Type

- Circular Saw Blade

- Capacity

- Up to 100 mm thickness (depending on machine compatibility)

- Weight (kg)

- Approx. 0.45-0.70

- Bond Type

- Resin Bonded

- Cutting Speed

- Up to 80 m/s

- Cutting Type

- Dry and wet cutting (machine dependent)

- Cutting Thickness

- 1.8 mm - 3.2 mm

- Segment No.

- 40 teeth

- Size

- 355 mm (14 inches) diameter

- Slot

- Standard continuous rim

- Teeth Type

- Tungsten Carbide Tipped (TCT)

- Feature

- High precision, reduced vibration, fast cutting

- Color

- Silver/Grey

Hitachi Metal cutting blades Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Hitachi Metal cutting blades

Direction Of Use & Application Media

To ace your metalworking tasks, simply mount the Hitachi blade onto compatible cut-off machines or chop saws, ensuring secure attachment through its preeminent 25.4 mm arbor hole. Use for dry or wet cutting of metal sheets, rods, pipes, and profiles. Benefit from extra features such as vibration and noise reduction, heat resistance, and a polished, anti-corrosive surface that maximizes operational efficiency and safety during robust applications.

Certifications, Market & FOB Port

Hitachi Metal cutting blades adhere to industry-leading certifications for performance and safety. Order completion is swift, with a rate guarantee at the lowest price for bulk procurements. These blades are exported mainly to India, Asia, and international markets via major Indian FOB ports, reliably supporting manufacturers and wholesalers seeking robust, high-speed metal cutting solutions. Grab this ace product to enhance productivity and ensure consistent quality with every consignment.

FAQ's of Hitachi Metal cutting blades:

Q: How do I properly mount and use Hitachi Metal Cutting Blades?

A: Securely fit the blade on a compatible cut-off machine or chop saw, ensuring correct alignment with the 25.4 mm arbor hole. Always follow machine safety protocols and select dry or wet cutting mode based on your application requirements.Q: What is the maximum material thickness these blades can cut?

A: Depending on the machine compatibility, Hitachi Metal Cutting Blades can efficiently cut through metal up to 100 mm thick, handling sheets, rods, pipes, and profiles.Q: When is noise reduction most beneficial during cutting operations?

A: Noise reduction is especially advantageous during prolonged or heavy-duty cutting cycles, as it minimizes workplace disruption and operator fatigue while maintaining high cutting precision.Q: Where can I purchase Hitachi Metal Cutting Blades at the lowest price?

A: You can procure these blades from certified wholesalers and manufacturers across India, often securing the lowest price during bulk purchases and direct order completions.Q: What process ensures heat resistance in these blades?

A: The blades are manufactured with enhanced heat-resistant high-speed steel and resin bonding, supported by a polished anti-corrosive coating that maintains structural integrity and cutting performance during intensive use.Q: What is the benefit of using Tungsten Carbide Tipped teeth?

A: Tungsten Carbide Tipped (TCT) teeth offer superior wear resistance and durability, allowing the blade to maintain sharpness and deliver rapid, precise cuts in various metals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hitachi abrasive and cutting blades Category

Hitachi Cup Wheel

Price 225 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Other, HighGrade Alloy Steel with Industrial Diamond Grit

Type : Other, Double Row Diamond Cup Wheel

Color : Other, Silver with Black or Yellow Segments

Bond Type : Metal Bond

Hitachi Circular saw blades

Price 150 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, High Carbon Steel

Type : Other, Tungsten Carbide Tipped

Color : Silver

Bond Type : Other, Brazed

Hitachi Wood Cutting Blades

Price 150 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Highgrade Hardened Steel

Type : Circular Saw Blade

Color : Silver

Bond Type : Other, Industrial Quality Brazed Carbide

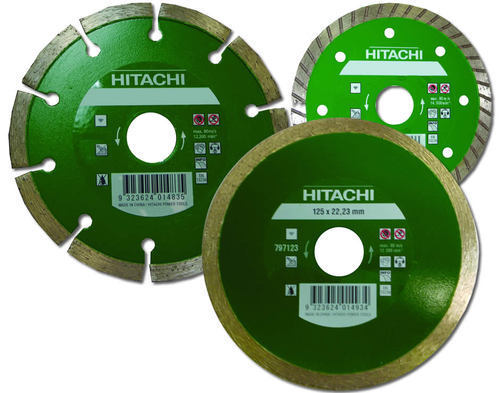

Hitachi Diamond Blades

Price 90 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Diamond

Type : Circular Saw Blade

GST : 27ALIPM3722C1ZD

|

|

POWERTEX MARKETING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry